Description

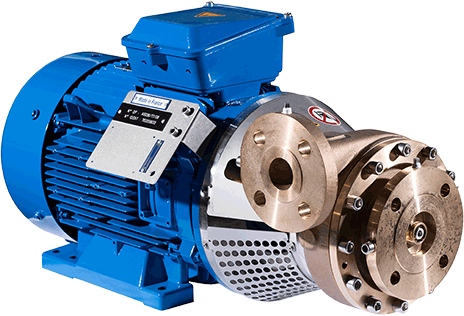

Cryogenic pumps are precision-engineered systems designed for the safe and efficient transfer of liquefied gases at extremely low temperatures. Built for continuous or intermittent operation, these pumps deliver stable flow rates, high discharge pressure, and exceptional reliability in demanding cryogenic environments.

Available in reciprocating, centrifugal, and submerged configurations, cryogenic pumps ensure optimized performance for applications such as cylinder filling, pipeline transfer, micro-bulk pressurization, and LNG fueling. Manufactured using high-grade stainless steel and advanced sealing technologies, they minimize thermal losses, resist wear, and maintain dependable performance even during long duty cycles.

Engineered to meet strict international standards, cryogenic pumps integrate safety features such as cavitation control, pressure relief, and temperature protection. They are ideal for gas companies, industrial facilities, laboratories, and energy infrastructure requiring consistent and efficient cryogenic fluid handling.

| Parameter | Specification |

|---|---|

| Pump Types | Reciprocating / Centrifugal / Submerged |

| Suitable Media | LIN, LOX, LAR, CO₂, LNG |

| Flow Capacity | 10 – 600 L/min (depending on model) |

| Discharge Pressure | Up to 350 bar (high-pressure filling pumps) |

| Material | Stainless steel cryogenic-grade components |

| Seal Type | Cryogenic mechanical seal / submerged seal |

| Insulation | Vacuum-jacketed or open cold-end |

| Operating Mode | Continuous / intermittent |

| Applications | Cylinder filling, LNG transfer, micro-bulk pressurization |

| Safety Features | Relief valves, cavitation protection, temperature safety |

| Certifications | CE / ISO / TPED / ASME (depending on model) |