Description

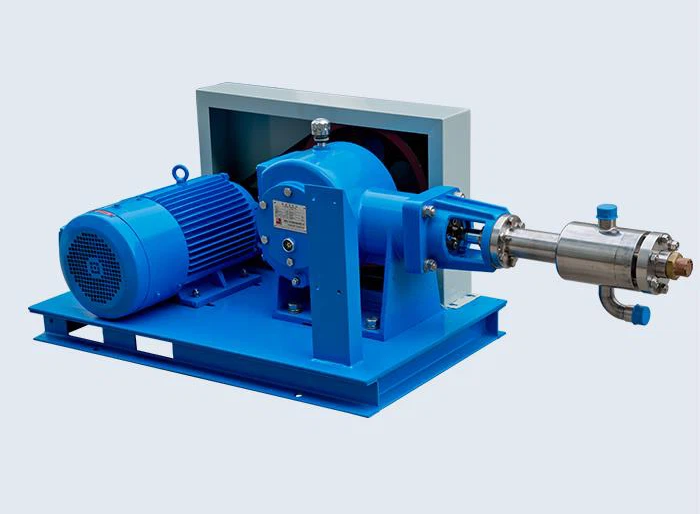

Reciprocating cryogenic pumps are engineered to deliver high-pressure, high-efficiency performance for transferring and filling liquefied gases such as liquid nitrogen (LIN), liquid oxygen (LOX), liquid argon (LAR), carbon dioxide (CO₂), and LNG. Their piston-driven design provides consistent discharge pressure and accurate flow control, making them ideal for cylinder filling stations, micro-bulk pressurization, cryogenic pipe transfer, and industrial gas supply systems.

Built with cryogenic-grade stainless steel components and advanced sealing technology, these pumps minimize thermal losses, resist wear, and ensure long service life in demanding low-temperature environments. They offer reliable operation under continuous or intermittent duty, with enhanced safety features such as overpressure protection, cavitation control, and temperature monitoring.

Reciprocating pumps are preferred for applications requiring high discharge pressure, precise dosing, and stable operation, especially in gas companies, industrial facilities, and laboratory environments.

| Parameter | Specification |

|---|---|

| Pump Type | Reciprocating piston pump |

| Suitable Media | LIN, LOX, LAR, CO₂, LNG |

| Flow Range | 5 – 200 L/min (model dependent) |

| Discharge Pressure | Up to 350 bar (cylinder filling) |

| Number of Stages | Single-stage / multi-stage options |

| Material | Stainless steel cryogenic-grade construction |

| Seal Type | Cryogenic mechanical seal |

| Cooling | Open cold-end design |

| Duty Cycle | Continuous or intermittent |

| Applications | Cylinder filling, micro-bulk pressurization, cryogenic transfer |

| Safety Systems | Pressure relief valve, temperature safety, cavitation protection |

| Standards | CE / ISO / TPED / ASME (depending on configuration) |